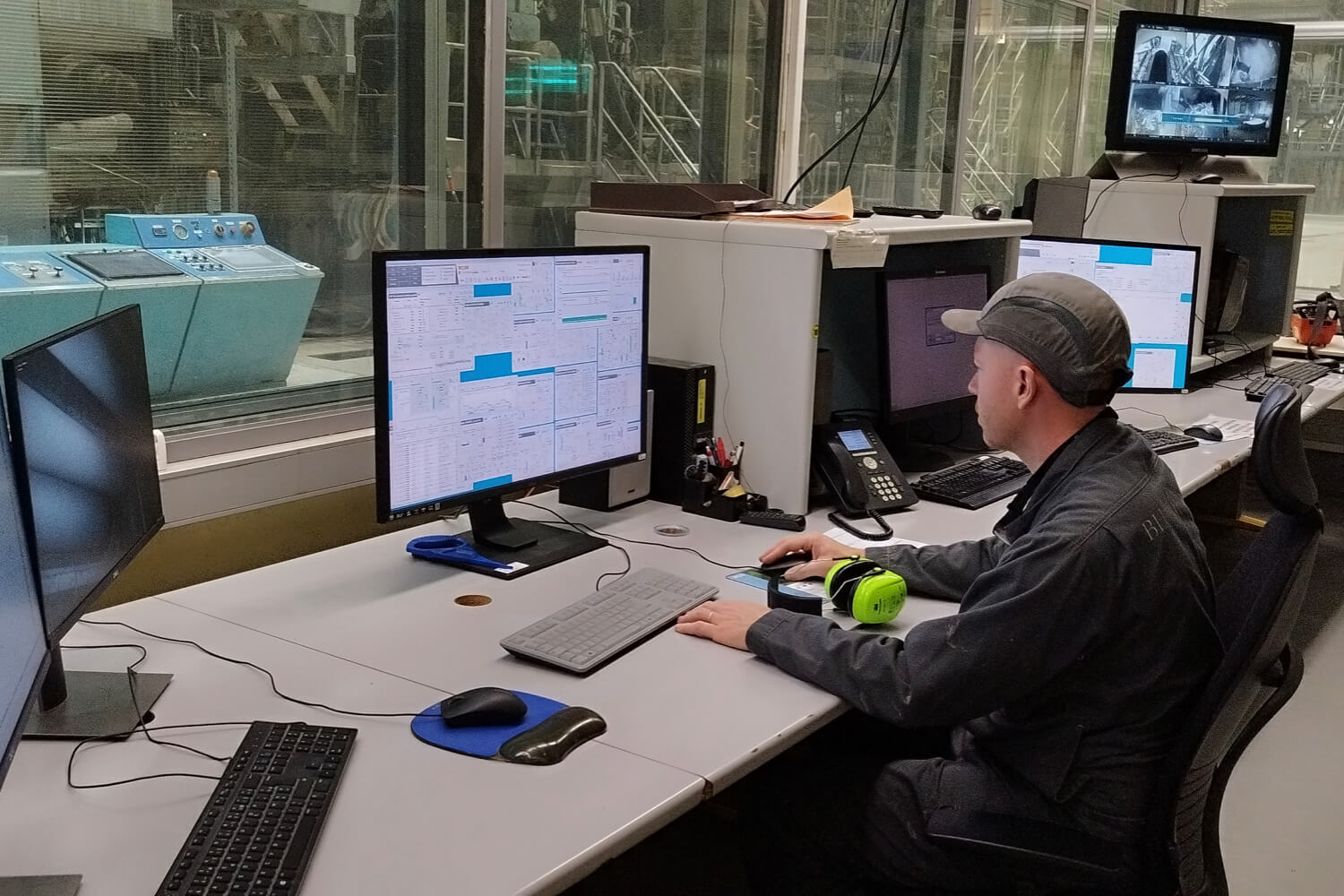

Line operator

The operator controls an installation (of varying size) which constitutes a sub-assembly corresponding to one of the phases in the paper-making process.

Working environment

He/she works in shifts, in continuous rotation. He/she must be fully conversant with the part of the process for which he/she is responsible.

At Blue Paper there are three categories of operator:

– pulper or OCC Operator: responsible for adjusting the pulp preparation line to ensure the production of the right quantity and quality of pulp according to the needs of the paper machine.

– paper Machine Operator: supervises machine settings and monitors key parameters to ensure good product quality, optimise production quantities and keep costs to a minimum.

– boiler and Water Treatment Operator: coordinates and optimises energy production. He/she is responsible for monitoring the quantitative and qualitative results of the energy and water treatment installations.

Skills and qualifications

Scientific baccalaureate or Bac Pro PCEPC (Chemical Processes for Water and Paper and Cardboard), BTS in Process Management, BTS in Electrical Engineering, but also Certification de Qualification Professionnelle (CQP) de Conducteur Machine à Papier or Certification de Qualification Professionnelle Interbranche (CQPI) de Conducteur d’Equipements Industriels or CQP en Bio-Energie.